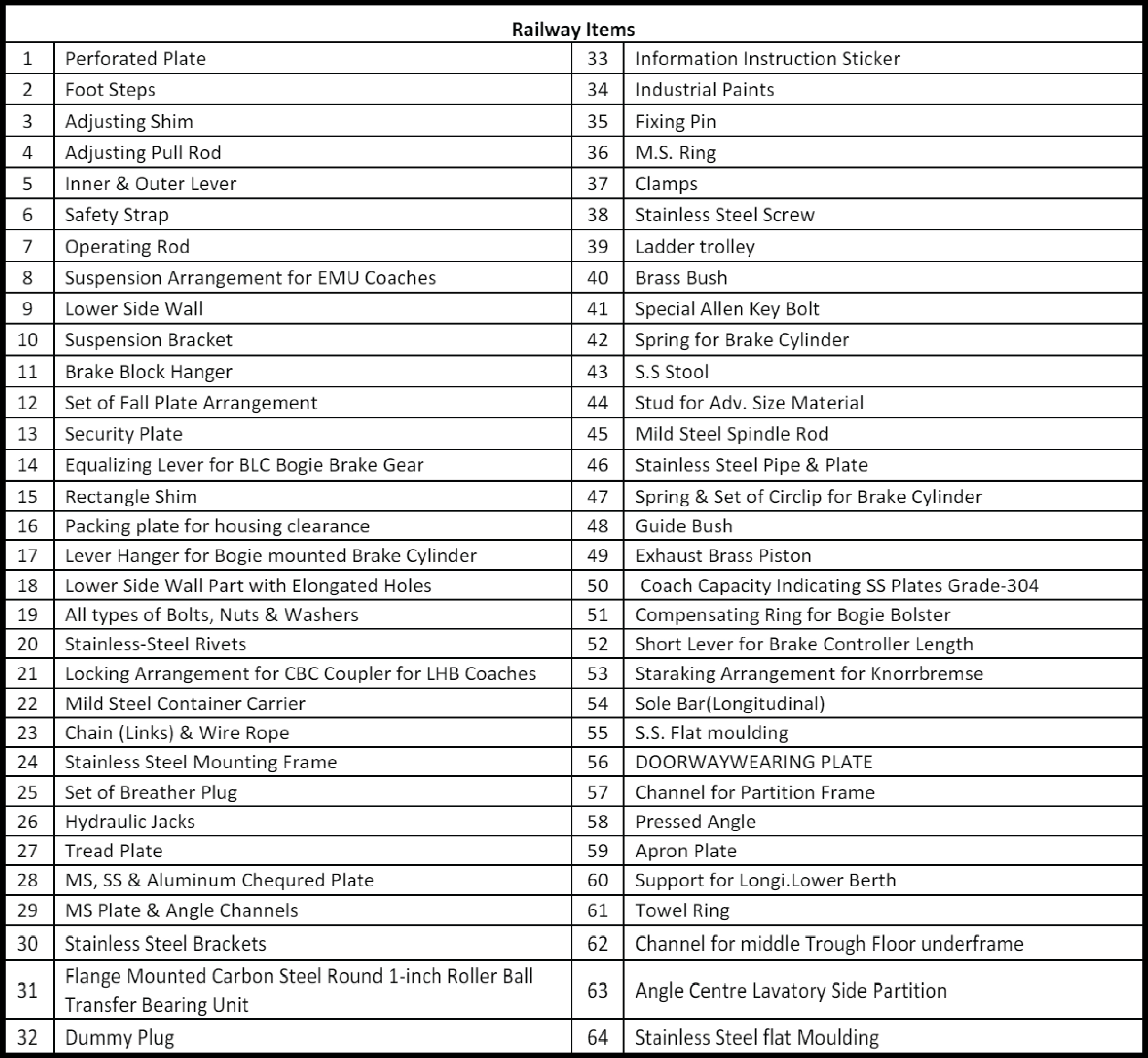

Services

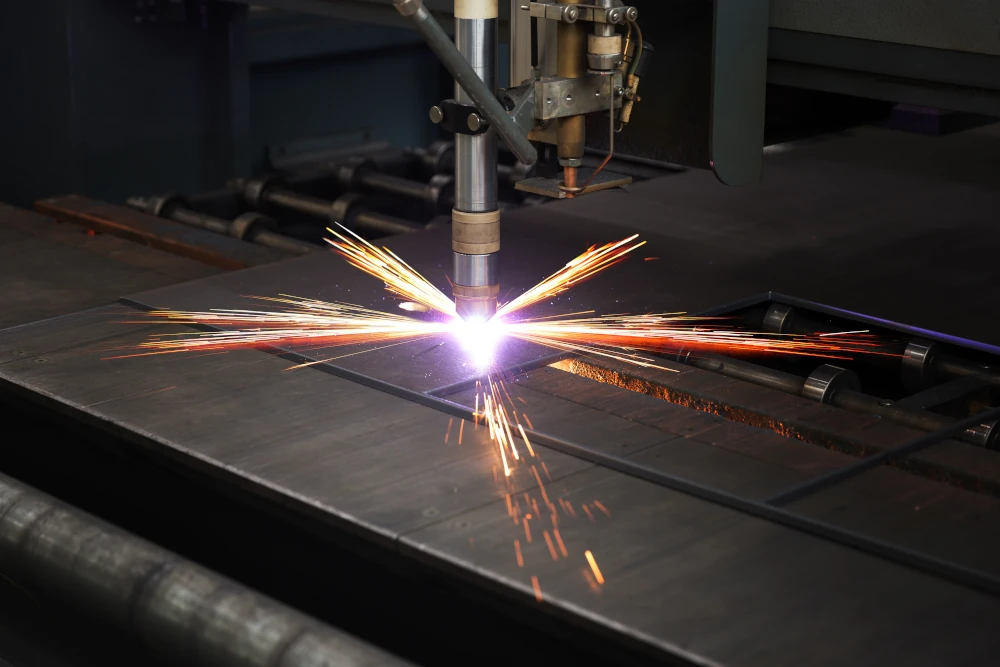

Laser Cutting Services

Laser cutting is a technology that uses a laser to vaporize materials, resulting in a cut edge. A commercial laser for cutting materials uses a motion control system to follow a CNC or G-code of the pattern to be cut onto the material. The focused laser beam is directed at the material, which then either melts, burns, vaporizes away, or is blown away by a jet of gas, leaving an edge with a high-quality surface finish.

Lasercraft Engineers LLP provides high quality Laser Cutting Services in Mumbai. Our new Laser Cutting machine (HSG 6KW) has a capacity of up to 25mm for MS and 16mm for SS material.

CNC Bending

Computer numerically controlled (CNC) bending is a manufacturing process that is carried out by CNC press brakes (also known as CNC brake presses). These machines can bend sheet metal work from just a few mm across to sections many metres long on the largest industrial machines.

Our CNC Machine has a capacity of 200 Tonnes with 3 mtr length.

Shearing

Shearing, also known as die cutting, is a process that cuts stock without the formation of chips or the use of burning or melting. Strictly speaking, if the cutting blades are straight the process is called shearing; if the cutting blades are curved then they are shearing-type operations. The most commonly sheared materials are in the form of sheet metal or plates. However, rods can also be sheared. Shearing-type operations include blanking, piercing, roll slitting, and trimming. It is used for metal, fabric, paper and plastics.

Punching

Punching uses a punch press to create holes in a workpiece by forcing a punch through the material, often into a die. It's common with sheet metal, paper, vulcanized fibre, and some plastics. The scrap left from the process can be recycled or discarded.

Punching is a cost-effective way to create holes in medium to high production volumes. When a special punch cuts multiple usable parts from a sheet, it's called blanking. If the process is done while the material is hot, it's known as hot punching.

Welding

Welding is a fabrication process that joins materials, usually metals or thermoplastics, by using high heat to melt the parts together and allowing them to cool, causing fusion. Welding is distinct from lower temperature metal-joining techniques such as brazing and soldering, which do not melt the base metal.

In addition to melting the base metal, a filler material is typically added to the joint to form a pool of molten material that cools to form a joint that, based on weld configuration, can be stronger than the base material (parent metal).

Our factory is well-equipped with TIG & MIG welding machines.

Grinding

Grinding is a type of abrasive machining process which uses grinding wheel as cutting tool.

Grinding is a subset of cutting, as grinding is a true metal-cutting process. Each grain of abrasive functions as a microscopic single-point cutting edge (although of high negative rake angle), and shears a tiny chip that is analogous to what would conventionally be called a “cut” chip (turning, milling, drilling, tapping, etc.)[citation needed]. However, among people who work in the machining fields, the term cutting is often understood to refer to the macroscopic cutting operations, and grinding is often mentally categorized as a “separate” process. This is why the terms are usually used separately in shop-floor practice.

Powder Coating

Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike conventional liquid paint which is delivered via an evaporating solvent, powder coating is typically applied electrostatically and then cured under heat or with ultraviolet light. The powder may be a thermoplastic or a thermoset polymer. It is usually used to create a hard finish that is tougher than conventional paint. Powder coating is mainly used for coating of metals, such as household appliances, aluminium extrusions, drum hardware, automobiles, and bicycle frames. Advancements in powder coating technology like UV curable powder coatings allow for other materials such as plastics, composites, carbon fiber, and MDF to be powder coated due to the minimum heat and oven dwell time required to process these components.